Choose from Our Existing Products

Glass cups designed for high tempera"Select from our extensive range of ready-made glassware and customize it with your choice of colors, copy, decorations, logos, and packaging to it uniquely yours."

mal shock.

Glass cups designed for high tempera"Select from our extensive range of ready-made glassware and customize it with your choice of colors, copy, decorations, logos, and packaging to it uniquely yours."

mal shock.

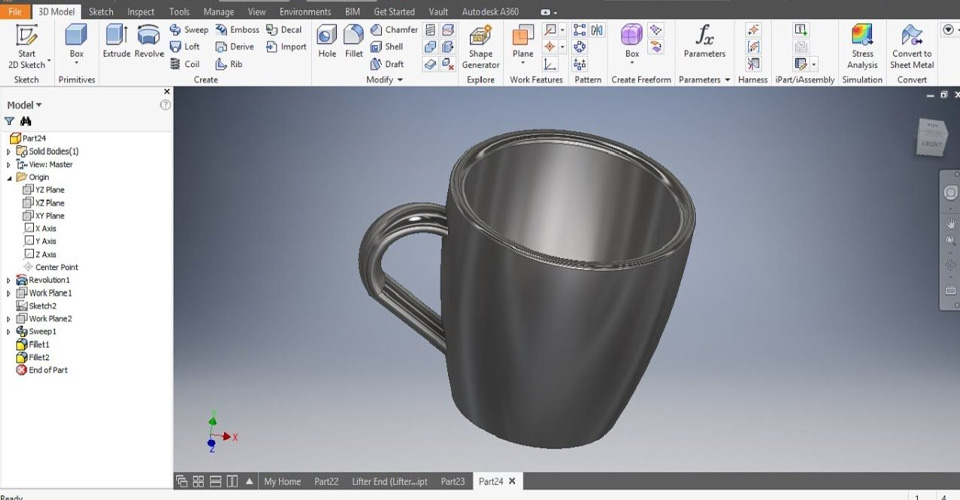

Provide us with your design blueprints, and we will craft exclusive molds to produce your custom-designed glassware. Alongside your unique shape, incorporate any of our standard customization options for a fully personalized product.

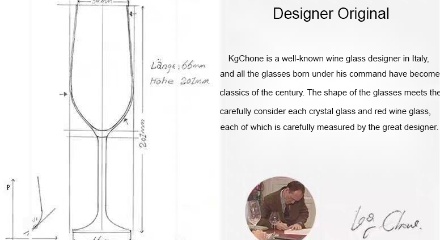

If you have an idea but no set design, we're here to bring it to life. After understanding your vision, we'll provide tailored design solutions to create a glassware series that perfectly captures your style.